There are five main phases in extrusion pellet production:

Production starts off with an appropriate selection of the raw materials – correctly balanced and mixed flours which then feed our extrusion system. Le Caselle has different extruders which enable work at different temperature levels and multiple types of extrusion screws, allowing proper cooking of raw materials with different origins.

We can therefore properly cook potato, cereal or legume-based flours getting an appropriate gelatinization of the starches and a good cooking of the proteins for our pellets whether they are to be fried or hot-air expanded.

Fried pellets are mainly connected to the snack market targeted at “Pleasure”, while hot-air expanded products are aimed at the “Heath” market.

The first conceptualization of a hot-air expanded snack took place in 2004, opening the road to the development of recipes adapted to the expansion of light snacks with extremely reduced fat content. Various clients from all over the world are interested in these new ways of creating healthy, light but very tasty snacks with lots of flavouring possibilities.

The need to respect the restrictive variation standards in the pellets’ key attributes has ensured the very top performance when they are being refined by our clients on their premises.

Our product’s key attributes are shape, consistency and basic taste, which then has to be joined together with the final flavouring applied by our clients after the snack’s expansion.

Macro categories

Diecut

There’s still a great market demand and approval for what were the first types of pellet we produced, especially with tubes and sticks.

Laminate

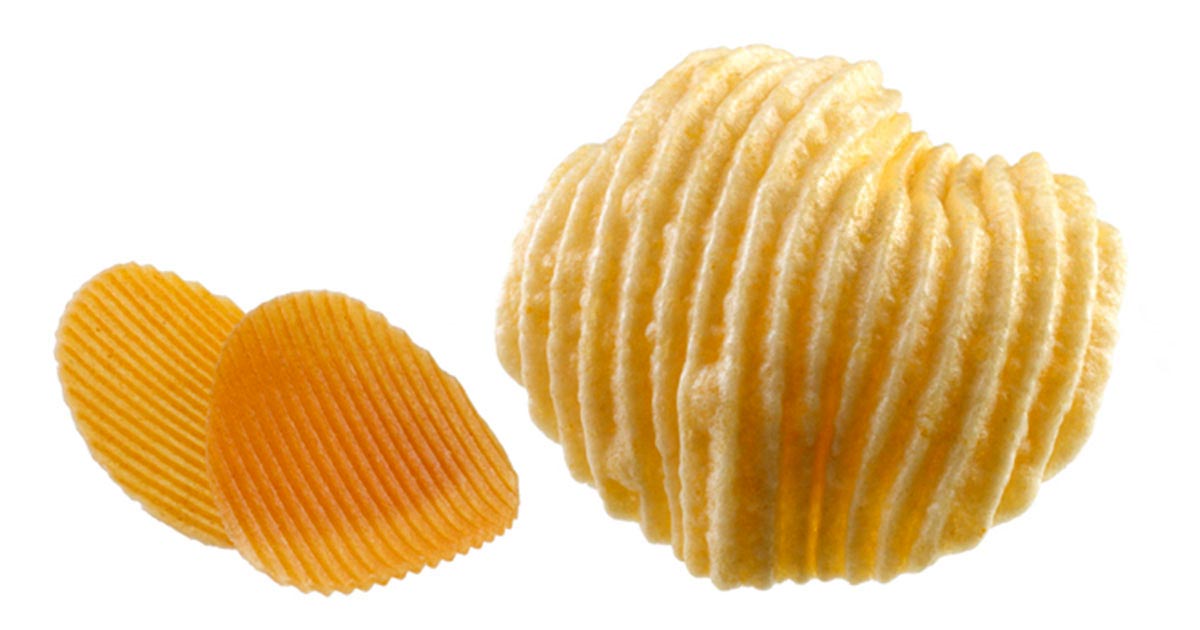

This is the classic evergreen product with a flat, wavy or crinkled surface, often cut in a round shape.

3D Slit

This is our most successful pellet; it satisfies the demands for a sensory appeal and for design both in the texture and the flavour.

Strips

These are pellets suited to the different expansion techniques and are also an excellent solution when using more varied ingredients is needed in order to achieve captivating flavour and consistency.

Stamped and perforated

This is the final frontier developed in shaping technologies. It’s particularly for those who need to add flavour with spicy or fruity aromas, and provides the best quality for hot air expanded pellets.